Gloves play a crucial role in maintaining asepsis during medical procedures, but can nitrile gloves withstand the autoclaving process? Research indicates that nitrile gloves can indeed be autoclaved, with minor degradation in material properties. Studies show that autoclaved nitrile gloves maintain performance through tests like visual inspection, stretching, and pressure tests. Despite some surface changes, their mechanical properties remain intact, making them a viable option for cost-effective aseptic procedures like rodent surgeries. Let’s investigate into the detailed considerations and limitations of autoclaving nitrile gloves for optimal performance.

Table of Contents

- Material Integrity

- Synthetic Rubber Properties

- Performance Expectations after Autoclaving

- Performance Testing

- Visual Inspection

- Stretch Tests

- Pressure Tests

- Thermal Stability

- Effects of Autoclaving on Nitrile Gloves

- Comparison to Non-Treated Gloves

- Mechanical Properties

- Tensile Strength and Modulus

- Elongation at Break

- Surface Morphology

- Microcracks and Voids

- Impact on Overall Performance

- Chemical Resistance

- Thermal Breakdown of Nitrile Material

- Compromised Protective Capabilities

- Applications and Limitations

- Rodent Surgeries and Cost-Effective Alternatives

- Manufacturer Guidelines and Specific Type Considerations

Material Integrity

Synthetic Rubber Properties

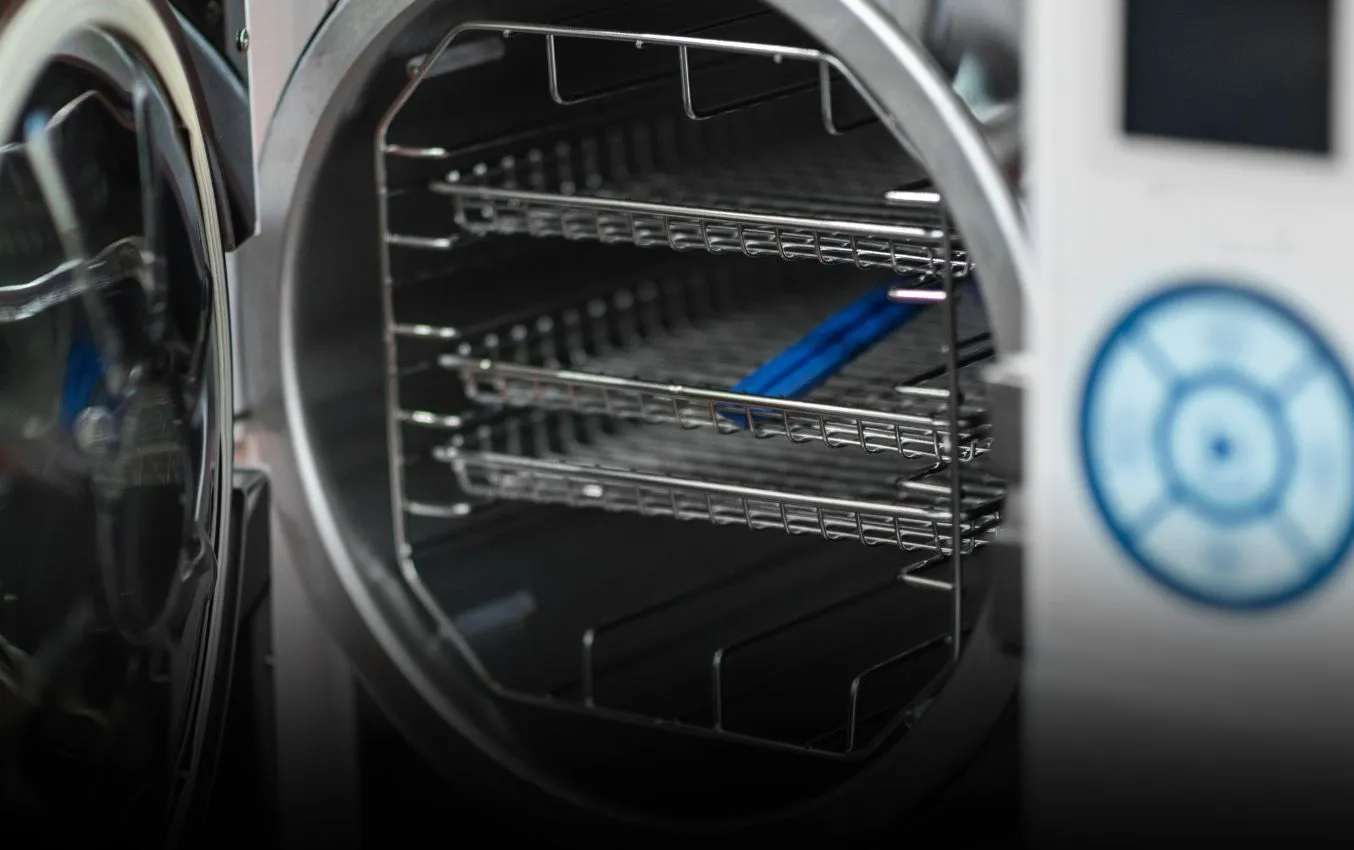

Before stepping into the world of autoclaving nitrile gloves, it’s necessary to understand the material they are made from. Nitrile gloves are crafted from synthetic rubber, known for its durability and resilience. However, when subjected to the autoclaving process, there may be some degradation in material properties to keep in mind.

Performance Expectations after Autoclaving

Expectations are crucial when considering autoclaving nitrile gloves. A study found that the vast majority of autoclaved nitrile exam gloves met performance expectations, with 98% of gloves performing as well as standard surgical gloves. This suggests that, despite potential material changes, autoclaved nitrile gloves can maintain their integrity and effectiveness for various applications.

It is vital to recognize that while there may be some degradation in material properties, the overall performance of autoclaved nitrile gloves remains satisfactory for usage. By undergoing rigorous performance testing, including visual inspections and stretch tests, these gloves have proven to be durable and reliable for aseptic procedures like rodent surgeries.

Performance Testing

Visual Inspection

On visual inspection, autoclaved nitrile gloves demonstrated minimal defects, maintaining their integrity and performance levels. This was supported by a study where 98% of autoclaved nitrile exam gloves met performance expectations compared to standard surgical gloves.

Stretch Tests

Visual and stretch tests confirmed that autoclaved nitrile gloves performed well, showing minimal defects and maintaining acceptable performance levels. The mechanical properties of the gloves, such as tensile strength, modulus, and elongation at break, were evaluated after repeated sterilization cycles, with results showing no significant change from baseline values.

Pressure Tests

With pressure tests, autoclaved nitrile gloves displayed reliability and durability during testing. The study confirmed that autoclaved nitrile gloves performed well in various tests, including pressure tests, indicating their suitability for use in aseptic rodent surgery. While the performance testing of autoclaved nitrile gloves showcased their durability and reliability, it is important to consider potential minor degradation in material properties. The study highlighted that nitrile gloves can maintain their performance and integrity to a satisfactory extent after autoclaving, making them a viable option for certain applications where cost-effective alternatives to sterile surgical gloves are required. Autoclaved nitrile gloves offer a reliable and cost-effective option for maintaining asepsis in surgical procedures, providing a valuable solution for various medical settings.

Thermal Stability

Effects of Autoclaving on Nitrile Gloves

For nitrile gloves, the thermal stability after multiple sterilization cycles, including autoclaving, remains consistent. Physical sterilization methods like steam (autoclaving) do not significantly alter the degradation behavior of nitrile gloves compared to non-treated gloves.

Comparison to Non-Treated Gloves

| Property | Autoclaved Nitrile Gloves |

| Thermal Stability | Consistent after autoclaving |

To further understand the comparison between autoclaved nitrile gloves and non-treated gloves, it’s crucial to note that autoclaved nitrile gloves maintain their thermal stability even after undergoing autoclaving processes. This indicates that the gloves can endure repeated sterilization cycles without significant changes in properties, ensuring their reliability and performance. A

| Property | Non-Treated Nitrile Gloves |

| Thermal Stability | Potential degradation over time |

The comparison highlights that non-treated nitrile gloves may experience degradation in thermal stability over time, unlike autoclaved nitrile gloves that maintain their consistent performance. This distinction underscores the benefits of autoclaving nitrile gloves to ensure their reliability and longevity in various applications.

Mechanical Properties

Tensile Strength and Modulus

Despite undergoing multiple sterilization cycles, including autoclaving, nitrile gloves maintained their mechanical properties such as tensile strength and modulus. The study showed no significant change from the baseline values, indicating the gloves’ ability to retain their structural integrity and strength.

Elongation at Break

Mechanical testing also revealed that the elongation at break of nitrile gloves remained consistent after autoclaving. This property is crucial in ensuring that the gloves can stretch without breaking, providing flexibility and comfort for the wearer during use.

To further elaborate, elongation at break measures the ability of the material to stretch before breaking. The fact that autoclaved nitrile gloves maintained this property indicates their durable nature and suitability for various applications, including surgical procedures.

Surface Morphology

Microcracks and Voids

Voids can sometimes be observed on the surface of nitrile gloves after autoclaving, along with minor microcracks. However, these changes are typically minimal and do not significantly impact the overall performance of the gloves, as indicated by a study on stability under repeated disinfection cycles.

Impact on Overall Performance

Microcracks and voids may be present on autoclaved nitrile gloves, but these surface changes are not substantial enough to affect the gloves’ functionality. The study on nitrile gloves’ performance after multiple sterilization cycles showed that while some surface morphology alterations were detected, they did not lead to a significant decline in the gloves’ mechanical properties or integrity.

Chemical Resistance

Thermal Breakdown of Nitrile Material

ResistanceKeep in mind that while nitrile gloves are known for their chemical resistance, they may not be as resilient to high temperatures in an autoclave. The thermal stability of nitrile gloves was evaluated after repeated sterilization cycles, showing that the nitrile material did not significantly change its degradation behavior compared to non-treated gloves.

Compromised Protective Capabilities

NitrileIt is crucial to note that the high temperatures in an autoclave can cause the nitrile material to break down, potentially compromising the gloves’ protective capabilities. While nitrile gloves excel in chemical resistance, their thermal resistance may be impacted during autoclaving, affecting their ability to provide full protection against external elements.

This emphasizes the importance of understanding the limitations of autoclaving nitrile gloves and ensuring that they are suitable for the specific application at hand. While autoclaved nitrile gloves offer a cost-effective option for certain procedures, it is crucial to consider the potential impact on their protective capabilities when exposed to high temperatures.

Applications and Limitations

Rodent Surgeries and Cost-Effective Alternatives

To address the need for cost-effective alternatives in rodent surgeries, autoclaved nitrile gloves have shown promising results. Studies have demonstrated that autoclaved nitrile gloves can maintain their integrity and performance levels, making them a viable option for aseptic rodent surgeries.

Manufacturer Guidelines and Specific Type Considerations

When considering autoclaving nitrile gloves, it is crucial to follow the manufacturer’s guidelines and assess the specific type of gloves being used. This ensures that the gloves can withstand the autoclaving process and maintain their performance without significant degradation.

Type-specific evaluations are important to determine the compatibility of nitrile gloves with autoclaving. It is recommended to consider factors such as material integrity, performance testing, thermal stability, mechanical properties, and surface morphology to ensure the gloves can withstand multiple sterilization cycles effectively.

The ability to autoclave nitrile gloves provides a valuable option for maintaining aseptic conditions in various settings, such as survival rodent surgery. While some minor degradation in material properties may occur, overall performance levels remain satisfactory, making autoclaved nitrile gloves a cost-effective and reliable choice. By following manufacturer guidelines and considering the specific type of nitrile gloves used, autoclaving can be a viable method for ensuring safety and sterility in procedures where sterile gloves are required.