Picture a busy line on the factory floor. Someone pulls on a fresh pair of disposable gloves, starts working, and within a few minutes one fingertip splits open on a sharp edge. Now there is a pause, a new pair, another few cents gone, and a little more frustration added to the shift.

Table of Contents

- What To Look For When Choosing Nitrile Exam Gloves

- Understanding Inspire Nitrile Exam Gloves: Core Material And Construction

- Key Features That Make Inspire Gloves Stand Out

- InSoft™ Formulation Technology

- Enhanced Fingertip Texture For Superior Grip

- Heavy-Duty 6 Mil Option For Demanding Tasks

- Color Options With Functional Purpose

- Real-World Benefits For Factory Workers

- How Inspire Nitrile Gloves Compare To Competitors

- Choosing The Right Size And Packaging Option

- Practical Applications Across Different Factory Roles

- What Customers Are Saying: Real User Experiences

- Making The Purchase: Where To Buy And What To Expect

- Conclusion

- FAQs

- Are Inspire Nitrile Gloves Truly Latex-Free And Safe For People With Latex Allergies?

- What Is The Difference Between The Standard And Heavy-Duty Inspire Gloves?

- How Long Can I Wear Inspire Gloves Before Needing To Change Them?

- Can Inspire Nitrile Gloves Be Used For Food Handling?

- What Makes The 300-Count Saver Pack A Better Value Than Standard Boxes?

- Do Inspire Gloves Work With Touchscreen Devices?

That scene plays out all day in plants and shops that use thin, cheap nitrile exam gloves or latex gloves that leave hands sweaty, tired, or covered in powder. Add co‑workers with latex allergies, long shifts, oils and solvents, and the cost of wasted gloves, and hand protection stops feeling like a small detail. It turns into a daily headache.

I created Nitrile Gloves Info because I kept seeing that same problem. Factory workers needed gloves that last, feel good, and protect against real hazards. In this article, I walk through how Inspire Nitrile Exam Gloves handle those needs. I cover:

- what to look for in any exam-grade glove,

- what makes Inspire different,

- how Inspire compares to common options, and

- how to pick the right size and packaging for a plant or shop.

By the end, it should be much easier to decide if Inspire is the right fit for your team.

What To Look For When Choosing Nitrile Exam Gloves

Before I talk about Inspire Nitrile Exam Gloves, it helps to have a simple checklist for any medical nitrile gloves used on the factory floor.

When I evaluate disposable nitrile gloves, I focus on:

- Material: Synthetic nitrile gives strong chemical resistance and avoids the allergy risk that comes with natural latex. That makes it a safer base for medical examination gloves and many industrial tasks.

- Durability vs. dexterity: Glove thickness, usually measured in mils, affects puncture resistance and tactile feel. Thinner gloves help with tiny parts and fine controls, while thicker gloves act more like puncture‑resistant gloves for sharp or rough work.

- Comfort and fit: Comfort is just as important as protection. I look for powder‑free exam gloves with a fit that does not squeeze the fingers or leave extra material bunching up. Gloves that fight the shape of the hand lead to fatigue and more tearing.

- Certification: Exam‑grade or medical‑grade labels show that the gloves pass strict tests for barrier strength and pinholes. That testing matters when workers rely on gloves as a primary barrier against contaminants and fluids.

- Practical details: Small details make a big difference day to day:

- a full size range,

- color for visibility and contamination control,

- packaging that keeps boxes full at busy stations, and

- ambidextrous nitrile gloves so nobody wastes time matching left and right.

With these points in mind, it becomes much easier to see how Inspire stacks up.

Understanding Inspire Nitrile Exam Gloves: Core Material And Construction

Inspire Nitrile Exam Gloves are built from quality stretch nitrile, which is a synthetic rubber rather than natural latex. In a factory, that choice matters. Nitrile stands up better to oils, greases, and many solvents than latex or vinyl, and it does not carry the proteins that cause latex allergies. For teams that include people with sensitive skin or known allergies, that alone removes a major safety concern.

Compared with latex, nitrile tends to resist punctures and tears better, which is why it has become the standard for many healthcare exam gloves and demanding industrial work. Vinyl is cheaper, but it tears more easily and offers weaker chemical protection, so I rarely recommend it for jobs beyond light cleaning.

Inspire gloves are exam‑grade medical nitrile gloves, which means each batch must meet strict requirements for barrier integrity, tensile strength, and stretch before it can reach users. That exam‑grade status is a key difference between Inspire and bargain gloves intended only for low‑risk tasks.

The material Inspire uses has a strong stretch profile without feeling rubbery or loose. When I say “quality stretch,” I mean the glove molds around the hand, then snaps back when removed instead of staying baggy. That snug fit helps with grip and fine control on small fasteners or electronic parts. Because these are powder‑free exam gloves, there is no cornstarch dust to bother skin, contaminate parts, or leave residue on tools and controls.

Cranberry USA, the maker behind Inspire Nitrile Exam Gloves, focuses on consistent production runs, so the gloves from one case feel and perform like those from the next. That kind of repeatable quality is important when a safety manager wants to standardize one type of glove across many roles in a facility.

Here is a quick material comparison that shows where nitrile fits among common glove types.

| Property | Nitrile | Latex | Vinyl |

|---|---|---|---|

| Chemical resistance | Strong against many oils and solvents | Moderate, weak against many oils | Weak to moderate |

| Puncture resistance | High for exam‑grade thickness | Moderate | Low |

| Allergy risk | Very low, no latex proteins | High for sensitive workers | Very low |

| Flexibility and feel | Very good with modern formulas | Excellent | Fair, can feel stiff |

| Typical uses | Medical, industrial, factory tasks | Medical, low chemical exposure | Light cleaning, low‑risk tasks |

Key Features That Make Inspire Gloves Stand Out

With the basics of material and construction in place, the next step is to look at what sets Inspire Nitrile Exam Gloves apart from standard disposable nitrile gloves. The brand uses a specific nitrile blend, grip design, and color system that all tie back to what happens during a shift on the line or in the shop. The details below explain how those design choices show up in day‑to‑day work.

InSoft™ Formulation Technology

One of the first things I notice with Inspire Nitrile Exam Gloves is how soft they feel compared with many other exam gloves. That comes from Cranberry’s InSoft™ formulation, a nitrile blend made to reduce stiffness without losing strength. Instead of fighting against tight, rigid material, the hands can move in a more natural way.

When a glove bends with the hand instead of pushing back, the muscles in the fingers, palm, and forearm do not have to work as hard. Over an eight‑ or twelve‑hour shift, that lower resistance can mean less cramping and fewer tired hands. For repetitive work such as packing, assembling, or checking parts, that difference adds up.

“Comfortable workers are safer and more productive workers. If PPE hurts to wear, people will find reasons not to use it.”

— Comment I often hear from safety managers who track glove compliance

I see InSoft as a quiet comfort feature that supports productivity, because people can keep their pace up longer without thinking about their gloves.

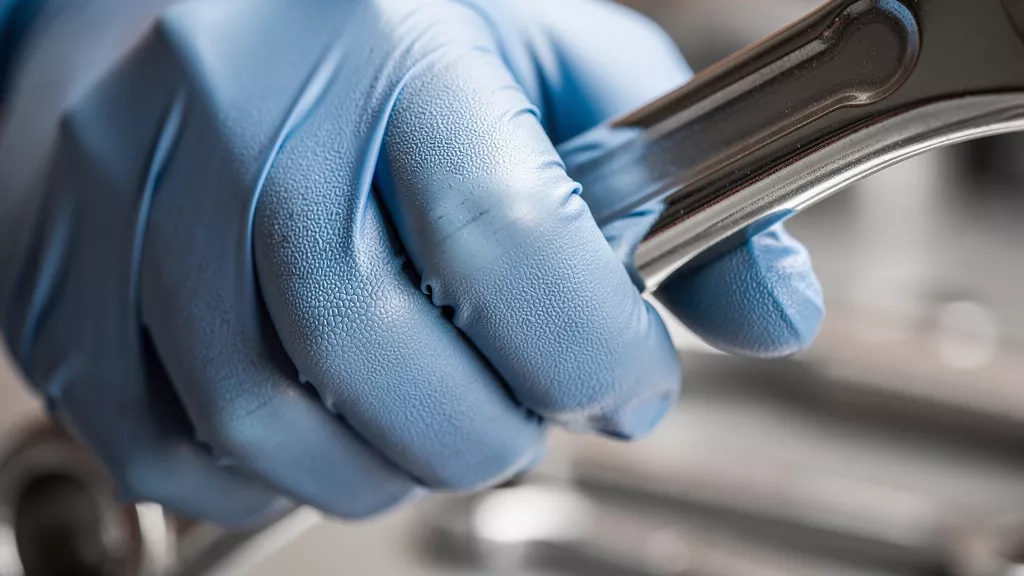

Enhanced Fingertip Texture For Superior Grip

Grip is one of the most important nitrile glove features for factory work, and Inspire does well here. The fingertips have a micro‑rough texture that adds friction without feeling sharp or sticky. When I run a finger along a metal part or a smooth plastic surface, I can feel that extra bite that keeps the item from sliding.

That texture really shows its value when conditions are less than perfect. A bit of oil mist, a damp part, or cleaner residue on a hand tool can make smooth gloves act like ice. Textured nitrile gloves like Inspire hold on better, which helps when:

- lifting small fasteners,

- handling glass or plastic parts, or

- using touch screens and control panels.

Better grip also supports safety, because fewer slips mean fewer dropped parts, fewer spills, and fewer chances for injury.

Heavy-Duty 6 Mil Option For Demanding Tasks

Not every job needs the same level of protection. Inspire Nitrile Exam Gloves come in a standard thickness for high‑dexterity tasks, and there is also a heavy‑duty version around 6 mil thick. One mil is one‑thousandth of an inch, so that extra thickness gives more physical barrier between the skin and sharp or rough materials.

I see the heavier glove as a good match for:

- maintenance and repair jobs,

- janitorial work with strong chemicals, and

- automotive and mechanical tasks where edges and burrs are common.

The heavier glove behaves like more protective puncture‑resistant gloves without turning the hand into a stiff club. Thanks to the same stretch formulation, finger movement stays smooth enough for gripping tools, turning fasteners, and pressing small buttons.

Color Options With Functional Purpose

Inspire Nitrile Exam Gloves are available in eye‑catching blues and black, and those colors do more than look nice. Aegean or cobalt blue makes it easy to spot pieces of glove material against food, electronics, or light parts, which supports contamination control. That bright color also helps supervisors see at a glance who is gloved in zones where protection is required.

The black heavy‑duty style hides grease, oils, and grime well, which keeps hands looking more professional in automotive bays or maintenance areas. Many plants also use different glove colors to separate departments or tasks—for example:

- blue for food zones,

- black for equipment work, and

- another color for quality inspection.

That color coding cuts the risk that a glove from a dirty task shows up in a clean one.

Real-World Benefits For Factory Workers

Features matter, but what really counts is what happens during a shift. When I talk with people who use Inspire Nitrile Exam Gloves on the job, several themes keep coming up.

The first is fewer torn gloves. Because the material is stronger than bargain options, workers usually get more time from each pair instead of stopping mid‑task to replace ripped fingers or palms. That cuts waste and helps keep lines moving.

Comfort is another clear benefit. The soft stretch fit and powder‑free feel make these comfortable exam gloves for long wear. Hands stay less cramped and less irritated, even when the gloves stay on through a whole break. Since they are latex‑free exam gloves, safety managers can standardize one glove choice without worrying about which workers can or cannot wear them.

“I used to go through several pairs an hour. With these, I can usually finish the job with one pair and my hands still feel okay afterward.”

Nitrile as a material offers good resistance to many oils, greases, and some solvents used for cleaning or degreasing. Users have mentioned that Inspire holds up better around harsh cleaners and even acetone compared with cheap disposable nitrile gloves. At the same time, the grip and tactile feel stay strong enough for small fasteners, buttons, and inspection tasks. The stain‑hiding colors and clean, powder‑free surface also help workers keep a professional look, even in dirty jobs.

How Inspire Nitrile Gloves Compare To Competitors

When people ask me about the best nitrile exam gloves for a factory, they often start from what they already know. That usually means boxes of generic nitrile exam gloves, or older latex styles left in supply closets. Compared with those, Inspire Nitrile Exam Gloves sit in a higher quality tier, and the difference shows up in both performance and long‑term cost.

Against generic economy nitrile, Inspire wins on tear resistance and wear time. A cheaper glove may cost a few cents less per pair, but if workers have to change gloves twice as often because of rips, the real cost per shift is higher. Inspire also has better grip texture and more consistent sizing, which helps with both safety and comfort.

Compared with latex gloves, Inspire avoids the allergy problem completely and gives stronger resistance to oils and many solvents. Older thinking said latex always gave better feel, but modern nitrile blends like InSoft close that gap enough that most workers do not miss latex at all.

When I compare Inspire with other name‑brand nitrile options, the big wins are:

- the softness of the material,

- the color choices, and

- the optional 300‑count saver pack.

Here is a side‑by‑side look at Inspire and two common alternatives.

| Feature | Inspire Nitrile Exam Gloves | Generic Nitrile Gloves | Latex Gloves |

|---|---|---|---|

| Base material | Quality stretch nitrile | Basic nitrile | Natural rubber |

| Thickness options | Standard plus heavy‑duty 6 mil | Often one thin option | Varies, often thin |

| Powder free | Yes | Sometimes, not always | Often powdered or powder free |

| Grip texture | Textured fingertips | Light or smooth | Usually smooth |

| Allergy risk | Very low | Very low | Higher, latex sensitivity |

| Typical durability | High, fewer tears | Moderate, more tears | Moderate |

| Price category | Mid, strong value over time | Low upfront | Mid |

Choosing The Right Size And Packaging Option

Even the best gloves cause problems if the size is wrong. Inspire Nitrile Exam Gloves come in a wide range, usually from extra small through extra extra large, so most hands can find a good match. A glove that is too tight can strain hands and tear more easily, while one that is too loose can catch on parts or reduce fine control.

When someone is not sure about size, I suggest:

- Measure around the widest part of the palm, just below the knuckles, while the hand is flat.

- Match that number in inches to the glove size chart for the supplier. For many brands, around eight inches often means a medium, nine inches a large, and so on.

- Try a sample box in two nearby sizes to see which feels better during actual work, not just when putting the glove on.

Packaging is the other side of the sizing choice. Inspire Nitrile Exam Gloves are sold in:

- standard 100‑count dispenser boxes,

- larger 300‑count Ultra saver packs, and

- 1,000‑count cases for bulk use.

For most factory settings, I like the 300‑count box because it cuts how often stations run out, saves storage space, and reduces cardboard waste. High‑use zones like cleaning teams or assembly lines often gain the most from that format.

Practical Applications Across Different Factory Roles

One reason I recommend Inspire Nitrile Exam Gloves so often is how well they fit many different roles in the same facility.

- Assembly lines: The standard weight glove gives enough dexterity for tiny parts, wiring, or delicate products while still offering reliable barrier protection. The textured fingertips help prevent small components from slipping, and the powder‑free design keeps sensitive electronics and precision surfaces clean.

- Quality control and inspection: Inspectors gain from the combination of feel and protection. The thin, soft nitrile lets them sense surface defects, edges, or contamination by touch without leaving fingerprints on tested parts. Since the gloves are latex free, there is no need to separate workers or keep special stock for people with allergies.

- Maintenance and repair: Maintenance and repair crews tend to favor the heavy‑duty 6 mil option, often in black. That thicker glove stands up better to sharp edges on sheet metal, tools, and machinery while hiding grease and dirt.

- Food processing: For food processing workers, the exam‑grade rating and bright blue color support hygiene rules and make any glove pieces easy to spot if a tear happens near product.

- Janitorial and sanitation: Janitorial and sanitation teams use Inspire Nitrile Exam Gloves around strong cleaners and disinfectants, where nitrile’s chemical resistance shines. The gloves last longer under scrubbing and repeated contact with cleaning agents.

- Shipping and receiving: In shipping and receiving, the ambidextrous design helps workers grab gloves fast without sorting, and the quality stretch lets them pull gloves on and off many times during a shift without constant tearing.

As one warehouse supervisor told me, “When we switched to a better glove, complaints about rips dropped fast—and so did the number of half‑finished tasks left on the benches.”

What Customers Are Saying: Real User Experiences

Customer feedback is one of the strongest signals I look at when judging any glove line. Inspire Nitrile Exam Gloves have earned around 4.7 out of 5 stars from well over a thousand ratings online, with a large share of those at five stars. That tells me these gloves work in real shops and clinics, not just in lab tests.

Below are a few recurring themes I see in those reviews, shared in my own words.

- Many users praise the strength and reliability. They talk about using one pair through long tasks where cheaper gloves would have failed several times, and they notice that fingertips and palms hold up better around tools and rough surfaces. Several reviewers call them their regular glove for daily work because they trust them not to split at the worst moment.

- Cost savings come up often, even though Inspire is not always the lowest price per box. People explain that since they throw away fewer torn gloves, they order less often and deal with fewer stockouts. One cleaning business owner mentioned cutting glove waste so much that she could lower her monthly supply orders without changing her workload.

- Comfort during long wear is another big point. Reviewers mention that the gloves stretch slightly and then settle into a snug, natural fit instead of pinching. They say the material feels softer than other nitrile brands they have tried, and they notice less hand fatigue after long shifts where gloves stay on for hours.

- Workers who handle harsh products report that Inspire stands up well to many chemicals. Some mention using the gloves around strong cleaners and even acetone without the material quickly turning sticky or weak. That kind of real‑world confirmation backs up what the lab data suggests about nitrile’s chemical resistance.

- Many reviews come from healthcare and industrial professionals who use gloves every day. They call Inspire reliable, say they would recommend them to co‑workers, and often note that they reordered multiple times. When I see that pattern across both medical and factory environments, it tells me the gloves work across a wide range of tasks.

Making The Purchase: Where To Buy And What To Expect

Once a safety manager or buyer decides to test Inspire Nitrile Exam Gloves, getting the right product is the next step. These gloves are widely sold through industrial safety distributors, medical supply channels, and major online retailers. When placing an order, I make sure the full name matches “Inspire Nitrile Exam Gloves by Cranberry” so I know I am getting the correct model with the features described here.

For a first trial, I often suggest ordering smaller boxes in two nearby sizes so workers can give feedback on fit and feel. After that test run, it is easier to move to 300‑count boxes or full 1,000‑count cases for the sizes that see the most use.

Shipping times vary by supplier and volume, but most online orders arrive within several business days, while bulk orders through distributors may follow a regular restock schedule. Prices change with market conditions and quantity, yet when glove waste drops, the cost per actual hour of protection usually compares very well.

For deeper spec details and side‑by‑side comparisons with other nitrile exam gloves, I keep updated guides on Nitrile Gloves Info.

Conclusion

Factory workers deal with enough stress without fighting flimsy gloves that tear, cause hand fatigue, or trigger allergies. Good hand protection should shield against chemicals and rough materials, stay comfortable through long shifts, and still make sense for the budget. That is the standard I use when I review any disposable nitrile gloves for Nitrile Gloves Info.

Inspire Nitrile Exam Gloves meet that standard by combining a soft InSoft formulation with strong, exam‑grade nitrile and thoughtful design touches. The textured fingertips help keep a solid grip, the heavy‑duty 6 mil option supports tougher tasks, and the latex‑free, powder‑free design keeps both workers and products safer. Real user feedback backs this up, with high ratings and many reports of fewer torn gloves and better comfort over time.

When I compare Inspire with generic nitrile or older latex options, the numbers and the daily experience both point in the same direction. You may pay a little more per box, but you gain longer wear per pair, less waste, and happier hands on the line. If the current gloves in a plant are tearing often, causing complaints, or raising safety questions, it might be time to measure against the standard set by Inspire Nitrile Exam Gloves and consider making a change.

FAQs

Are Inspire Nitrile Gloves Truly Latex-Free And Safe For People With Latex Allergies?

I can confirm that Inspire Nitrile Exam Gloves are made from synthetic nitrile rubber with no natural latex proteins. That means they do not trigger the classic latex allergy reaction linked to those proteins. For workplaces with mixed teams, this makes them a safe single choice for everyone. There is no need to stock separate glove types for people with latex sensitivity.

What Is The Difference Between The Standard And Heavy-Duty Inspire Gloves?

The standard Inspire Nitrile Exam Gloves sit in the medium thickness range, which gives a good blend of protection and dexterity for assembly, inspection, and light cleaning. The heavy‑duty version is around six mil thick, so it offers stronger resistance to punctures, abrasions, and many chemicals. Both share the same soft InSoft material feel, so the decision comes down to how sharp, rough, or chemical‑heavy the tasks are.

How Long Can I Wear Inspire Gloves Before Needing To Change Them?

Wear time depends on what someone is doing and what they touch. For clean assembly or inspection work, many users report that a single pair can last most or all of a shift if there is no major contamination or visible damage. For jobs involving chemicals, body fluids, or heavy soil, gloves should be changed right after exposure or as local safety rules require. The higher durability simply means fewer unexpected changes from sudden rips.

Can Inspire Nitrile Gloves Be Used For Food Handling?

Yes, Inspire Nitrile Exam Gloves are suitable for handling food in many settings. Their exam‑grade rating means they provide a reliable barrier against germs, and the powder‑free surface does not leave residue on food products. Because they are latex free, they help protect both workers and consumers who may be sensitive to latex. The bright blue color also makes any torn pieces easier to see during food safety checks.

What Makes The 300-Count Saver Pack A Better Value Than Standard Boxes?

The 300‑count saver pack puts three times as many gloves into a box that is still easy to mount or place at a station. That higher count reduces how often someone needs to stop and change out empty boxes, which saves time and keeps lines running more smoothly. It also cuts cardboard waste since one box replaces three smaller ones. In many cases, the price per glove is lower than buying several standard 100‑count boxes.

Do Inspire Gloves Work With Touchscreen Devices?

In my experience and from user reports, Inspire Nitrile Exam Gloves work with many modern touchscreens, especially those with good sensitivity. The thin, snug fit helps the screen detect finger contact better than thick or loose gloves. That said, performance can vary between different devices and screen protectors. For tasks that depend heavily on touch input, I recommend testing a sample pair with the specific equipment used on the floor.