Every scratch, oil stain, and chemical splash on a mechanic’s hands tells a story. The shop may have steel-toe boots, safety glasses, and coveralls, yet the hands still take the hits first. That is exactly why learning how to choose gloves for automotive work matters far more than grabbing the cheapest box on the shelf.

Table of Contents

- Key Takeaways

- Why Nitrile Gloves Are the Top Choice for Automotive Work

- Understanding Glove Thickness: Finding Your Balance Between Protection and Dexterity

- 3–5 Mils: Maximum Dexterity for Precision Tasks

- 6–8 Mils: The Sweet Spot for General Automotive Work

- 8+ Mils: Heavy-Duty Protection for Demanding Tasks

- Chemical Resistance: Protecting Against Automotive Fluids and Solvents

- Essential Features That Enhance Performance and Safety

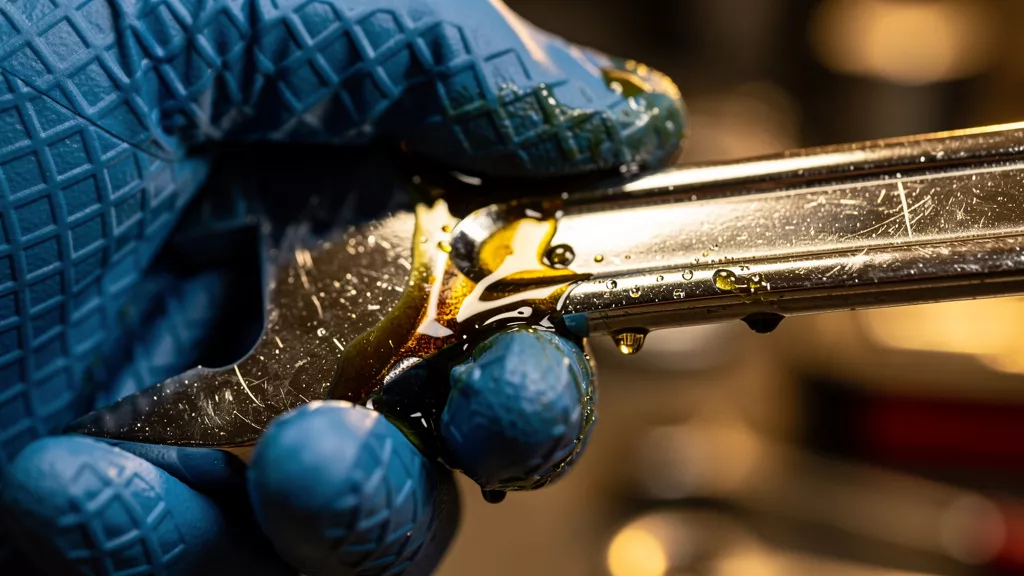

- Textured Surfaces for Superior Grip

- Powder-Free: The Only Professional Choice

- Color Considerations: Visibility and Practicality

- Achieving the Perfect Fit: Sizing and Comfort

- Task-Specific Glove Recommendations for Automotive Work

- Oil Changes and Fluid Service

- Brake Jobs and Handling Corrosive Chemicals

- Electrical Work and Precision Assembly

- General Repairs and Maintenance

- Proper Storage and Handling for Optimal Performance

- Environmental Considerations: Sustainable Options for High-Volume Use

- Conclusion

- FAQs

- What Makes Nitrile Gloves Better Than Latex or Vinyl for Automotive Work?

- How Do I Know If a Glove Has Adequate Chemical Resistance for Brake Fluid?

- Can I Reuse Disposable Nitrile Gloves to Save Money?

- What Glove Thickness Should I Use for Oil Changes?

- Why Are Powder-Free Gloves Required for Automotive Work?

- How Do I Find My Correct Glove Size?

- Related Posts

Automotive work brings constant contact with:

- Sharp metal edges

- Hot parts and exhaust components

- Harsh fluids like brake cleaner, gasoline, and solvents

Pick the wrong disposable glove and it can swell, tear, or let chemicals seep through. That leads to skin irritation, poor grip on tools, and even costly rework if contamination reaches paint, sealants, or internal components.

The challenge is that glove choice is not simple, as explained in guides on Types of Safety Gloves that outline the various options available. We have to balance chemical resistance, thickness, grip, fit, and comfort, while still keeping the feel needed to work on tiny fasteners or sensors. At Nitrile Gloves Info, we focus only on nitrile gloves, so we dig into the details that most general safety catalogs gloss over. We help mechanics, techs, and safety managers understand how to choose gloves for automotive work that match real shop conditions.

In this guide we cover material differences, thickness in mils, chemical resistance ratings, sizing, and task-based recommendations. We also talk about grip on oily parts, powder-free vs powdered, storage, and greener options for high-volume use. By the end, anyone who wants to know how to choose gloves for automotive work will have a clear checklist for picking disposable nitrile gloves that protect hands and support consistent, high‑quality work.

As many veteran technicians say, “Your hands are your first line of defense in the shop—treat them like a precision tool.”

Key Takeaways

Before diving into the details, it helps to see the big picture. These key points give a fast overview of how to choose gloves for automotive work that match real shop needs.

- Nitrile gloves stand out for automotive work. They resist oils and fuels very well and handle cuts and scrapes better than latex or vinyl.

- Glove thickness in mils shapes protection and feel. Thinner gloves give more touch and control; thicker gloves last longer and handle rougher tasks.

- Powder-free gloves protect work quality. Loose powder can land on paint or glass and interfere with sealants and gaskets during assembly.

- Fit matters as much as material. Loose gloves slip and catch on parts; tight gloves tire hands and tear faster in use.

- Different jobs need different gloves, even in one shop. Oil changes and brake work call for tougher options, while electrical work and fine assembly need thinner, more sensitive gloves.

- Chemical resistance ratings such as EN ISO 374-1:2016 help confirm protection. These markings show that gloves were tested against specific chemicals.

- Textured surfaces make a real difference with oily tools. Texture improves grip, cuts down on slips, and supports steady, confident work.

Why Nitrile Gloves Are the Top Choice for Automotive Work

When we talk about how to choose gloves for automotive work, we start with material. Nitrile has become the standard in auto shops because it handles the two biggest problems mechanics face: harsh chemicals and sharp parts. While latex and vinyl still appear in some garages, they rarely match what nitrile can do under real shop stress.

Nitrile is a synthetic rubber that stands up very well to petroleum-based fluids. Engine oil, gear oil, transmission fluid, gasoline, diesel, and most common solvents do not cause nitrile to swell or fall apart quickly. Latex and vinyl can soften, crack, or even dissolve in those same fluids, which defeats the point of wearing protection in the first place.

Strength is another area where nitrile stands out. Research on Protective gloves, hand grip strength shows nitrile is three to five times more puncture resistant than latex of the same thickness. That extra margin matters when knuckles brush against hose clamps, sharp body edges, or rough casting lines. A glove that resists small tears lets a mechanic finish a job without stopping every few minutes to change gloves.

Comfort also plays a big part in how to choose gloves for automotive work. Modern nitrile is far less stiff than older styles. After a few minutes of wear, nitrile softens and shapes to the hand. This “memory fit” cuts down on hand fatigue and keeps fine control for tasks like threading small bolts or clicking connectors together.

Some people still like latex for its stretch and “second-skin” feel, and vinyl for very light, low-risk tasks. We see those as narrow tools for special cases, not general shop work. Latex raises allergy concerns, and vinyl tears too easily around sharp parts. For most mechanics, nitrile gloves offer the best mix of chemical resistance, durability, and touch, which is why Nitrile Gloves Info bases our guidance around nitrile‑first choices.

For a quick comparison:

- Nitrile: Strong chemical resistance, high puncture resistance, latex-free

- Latex: Good feel and stretch, but poor resistance to many automotive fluids and potential allergies

- Vinyl: Low cost, but weak against chemicals and tearing; better suited to very light tasks only

Understanding Glove Thickness: Finding Your Balance Between Protection and Dexterity

Once we choose nitrile, thickness is the next big step in how to choose gloves for automotive work. Glove thickness is measured in mils, where one mil is one‑thousandth of an inch. A change of just a few mils can shift a glove from “bare-handed feel” to “armor against chemicals,” so this detail matters a lot.

In simple terms:

- Thicker gloves protect better and last longer.

- Thinner gloves let fingers feel more and move more freely.

No single thickness covers every job in a busy shop, so we like to think in three ranges: 3–5 mil, 6–8 mil, and 8+ mil. Each range fits a different style of task and should have a place in a well‑stocked cabinet.

When we teach how to choose gloves for automotive work, we usually suggest picking one “everyday” thickness, then adding thinner and thicker boxes for special jobs. The sections below walk through where each range makes sense.

3–5 Mils: Maximum Dexterity for Precision Tasks

Thin nitrile gloves in the 3–5 mil range feel close to working with bare hands. Fingers bend freely, and small changes in pressure still come through the material, as documented in A Survey of Glove-Based systems that examines how glove thickness affects hand movement data and tactile feedback. That makes this range a strong pick for delicate jobs where feel matters more than raw strength.

These lighter gloves work well for:

- Electrical diagnostics and module work

- Sensor replacement

- Handling small clips, pins, and connectors

- Interior trim, infotainment, and light detail work

Tasks such as plugging in tiny connectors, pressing clips, or seating O‑rings go smoother when the glove does not fight finger movement. These thin gloves also fit well where contact with harsh chemicals is limited.

The trade-off is simple: thin gloves tear more easily and do not last as long during heavy wrenching. When we talk about how to choose gloves for automotive work, we see this range as a short‑term, high‑dexterity option, not a glove to wear through a full brake job.

6–8 Mils: The Sweet Spot for General Automotive Work

For most mechanics, 6–8 mil nitrile gloves are the daily drivers. This range, often sold as “industrial‑grade,” offers a strong balance between protection and dexterity. The material is thick enough to resist many minor cuts and punctures, yet still flexible enough for steady tool control.

In this thickness, we feel comfortable tackling:

- Oil and filter changes

- Brake jobs (with the right chemical rating)

- Suspension work

- Cooling system service

- General engine repairs and under‑hood work

Gloves in the 6–8 mil range hold up well against drain plugs, filter housings, hose clamps, and sharp brackets. They usually last through a long task without shredding, which saves time and frustration.

When someone asks us how to choose gloves for automotive work if they only want one thickness on the shelf, we usually point to 6–8 mil nitrile. It is the most versatile choice for shops that handle a wide mix of repair and maintenance work every day.

8+ Mils: Heavy-Duty Protection for Demanding Tasks

At 8 mils and above, disposable nitrile gloves move into heavy‑duty territory. These gloves create a tougher barrier against long exposure to chemicals and rough mechanical contact. Fingers lose some fine feel, but gain serious armor.

We rely on 8+ mil gloves for:

- Engine overhauls

- Transmission or differential service

- Extended work with strong solvents and cleaners

- Jobs where hands scrape repeatedly over jagged castings or tight brackets

When hands stay inside harsh fluids or slide across rough metal, that extra thickness brings peace of mind. These gloves are less likely to fail mid‑job, even when soaked in cleaner or packed into tight spaces.

For how to choose gloves for automotive work in a busy shop, we suggest keeping at least one box of 8+ mil nitrile ready. They may not be used every day, but when a job gets ugly, mechanics are glad to have them.

Chemical Resistance: Protecting Against Automotive Fluids and Solvents

Chemical exposure is one of the biggest reasons how to choose gloves for automotive work matters so much. Many common automotive fluids can pass through or break down the wrong glove material, and skin can absorb some of those chemicals over time. That can lead to irritation, dermatitis, or more serious long‑term health problems.

In a normal week, a tech may handle:

- Engine oil and gear oil

- Transmission and power steering fluid

- Coolant and antifreeze mixes

- Gasoline and diesel

- Brake fluid (very aggressive)

- Parts cleaner, carb cleaner, and degreasers

Some of these fluids strip natural oils from the skin, while others contain additives that cause reactions after repeated contact.

Nitrile does a far better job than latex or vinyl against most petroleum‑based products. It resists swelling and softening when soaked in oil or fuel, so the barrier stays intact. That is a core reason nitrile sits at the center of how to choose gloves for automotive work in modern shops.

Not all nitrile gloves are equal, though. Thickness and the exact chemical blend of the nitrile both affect performance. For serious chemical exposure, it is smart to look for gloves that carry formal test markings. One key example is EN ISO 374-1:2016, a European standard that checks gloves against a list of hazardous chemicals. When a glove lists this standard, it signals that the manufacturer tested chemical resistance in a structured way.

We also advise reading the chemical compatibility chart from the glove maker. These charts list how long the glove material stands up to specific substances such as brake fluid, gasoline, or acetone. When in doubt, especially with strong solvents or long contact times, a more specialized chemical‑resistant glove may be needed. At Nitrile Gloves Info, we help readers connect these charts and standards to the real fluids sitting on their parts washer or shelf.

A common safety rule is, “If you wouldn’t put your bare hand in it, don’t trust a random glove with it either—check the data first.”

Essential Features That Enhance Performance and Safety

Material and thickness are the foundation, but smaller design choices can change how safe and comfortable a glove feels in daily work. When we explain how to choose gloves for automotive work, we pay close attention to grip, powder, and color. These details often separate an “okay” glove from one that mechanics actually like to wear.

Textured Surfaces for Superior Grip

Automotive work rarely involves dry, clean parts. Hands spend most of the day on oily filters, greasy bolts, smooth plastic covers, and metal tools that pick up fluid quickly. Without good grip, tools can slip, knuckles can hit sharp edges, and small parts can fall into tight spots.

Textured nitrile gloves address this problem directly. Many industrial gloves use:

- All‑over micro‑texture

- Diamond patterns

- Extra texturing on fingers and palms

These tiny raised areas increase contact between glove and tool, and they help channel thin layers of fluid away from the highest points. That design keeps more solid contact instead of letting the glove skate over wet metal.

When we talk through how to choose gloves for automotive work, textured surfaces always rank near the top of our wish list. A strong texture gives better control when loosening greasy drain plugs, holding impact sockets, or handling slippery filters. That improves safety and also helps jobs move faster, with fewer dropped tools and less wasted motion.

Powder-Free: The Only Professional Choice

Powder used to be common in disposable gloves, mainly to make them easier to put on sweaty hands. The powder is usually cornstarch, and it spreads very easily. In automotive work, that loose dust creates serious problems that outweigh any small comfort gain.

Powder can:

- Float onto wet paint and cause tiny craters (fisheyes) in the finish

- Land on glass or body panels and interfere with adhesives

- End up inside engines or transmissions as foreign particles

Because of these risks, professional shops choose powder-free gloves only. Modern powder‑free nitrile often uses a light polymer coating inside the glove so it still slides on without trouble. When explaining how to choose gloves for automotive work, we state it plainly: powder‑free is not just a preference, it is a requirement for any serious repair or paint shop.

Color Considerations: Visibility and Practicality

Glove color does more than set a style. It can help with safety, visibility, and even housekeeping:

- Bright orange or green gloves make hands stand out inside dark engine bays, under dashboards, or under a lift. That extra visibility supports accuracy and safety in tight spots.

- Black gloves stay popular because they hide grease and oil stains and give a clean look, while also offering strong contrast against light‑colored fluids and small metal parts.

- Blue or purple gloves often signal nitrile in mixed‑material workplaces and may be easier to spot if torn pieces fall into an engine bay or interior.

When choosing color, we like to match it to the lighting in the shop and the type of work done most often.

Achieving the Perfect Fit: Sizing and Comfort

Even the best nitrile material fails if the glove does not fit, which is why resources on How Do You Know if your gloves fit properly emphasize the importance of proper sizing for safety and performance. When we explain how to choose gloves for automotive work, we treat sizing as just as important as thickness. A glove that hangs off the fingers feels clumsy, catches on hardware, and dulls touch. A glove that is too tight strains seams, limits movement, and can tear right when a mechanic leans into a bolt.

The best starting point is to measure hand size instead of guessing. Use a soft tape and wrap it around the widest part of the hand, just below the knuckles, without including the thumb. Match that number to a size chart like the one below, then adjust based on brand notes and personal feel.

| Hand Circumference | Glove Size |

|---|---|

| 16–18 cm (6–7 in) | XS |

| 18–20 cm (7–8 in) | S |

| 20–22 cm (8–8.5 in) | M |

| 22–24 cm (8.5–9.5 in) | L |

| 24–26 cm (9.5–10.5 in) | XL |

| 26–28 cm (10.5–11 in) | XXL |

We also think about how different materials stretch when we show people how to choose gloves for automotive work. Nitrile and latex stretch more than vinyl and give a snug, form‑fitting feel once warmed by the hand. Nitrile in particular tends to relax and mold to the user after a few minutes, which many mechanics find more comfortable during long jobs.

A quick check for fit:

- Fingers should fill the glove without extra flapping at the tips.

- The glove should move with the hand without cutting into the skin.

- You should be able to make a tight fist without feeling seams about to pop.

Because sizing can vary by brand, we often suggest ordering a small mix of sizes when trying a new glove line. Wearing the right size reduces hand fatigue, helps maintain a secure grip, and prevents random tears when flexing or twisting the hand. For techs who wear gloves all day, that comfort becomes a real safety factor, not just a nice extra.

Many safety trainers repeat the same idea: “The best PPE is the gear people will actually wear all day.”

Task-Specific Glove Recommendations for Automotive Work

One of the most useful ways to think through how to choose gloves for automotive work is to match the glove to the job. Different tasks put stress on different parts of the glove and expose hands to different chemicals. Stocking only one thickness or style often means someone is working with too little protection or too little dexterity.

We like to group common shop work into four buckets: oil and fluid service, brake and strong chemical work, electrical and precision tasks, and general repairs. Each group lines up with a preferred glove thickness and feature set. With that approach, safety managers and techs can grab the right box without stopping to overthink every choice.

Oil Changes and Fluid Service

For oil changes and regular fluid service, 6–8 mil nitrile gloves hit the mark. They provide strong resistance to engine oil, gear oil, and other common fluids while still letting fingers move well around filters and drain plugs. The extra thickness protects against sharp threads and metal edges that often surprise hands near the oil pan.

For this work, look for:

- 6–8 mil nitrile

- Textured fingers and palms

- Powder‑free design

In guides on how to choose gloves for automotive work, we usually list 6–8 mil textured nitrile as the default choice for this very common task.

Brake Jobs and Handling Corrosive Chemicals

Brake work brings one of the harshest fluids in the shop. Brake fluid is very aggressive on skin and also on some glove materials. For these tasks we prefer chemical‑rated nitrile gloves at 8 mils or thicker, backed by clear test data.

Gloves used around brake fluid, carb cleaner, and strong degreasers should:

- List chemical resistance markings such as EN ISO 374-1:2016

- Be thick enough (often 8+ mil) for extended contact

- Be changed immediately if damaged, swollen, or sticky

When we explain how to choose gloves for automotive work that involves heavy chemical use, this level of detail is not optional; it is part of safe practice.

Electrical Work and Precision Assembly

Fine electrical work and small assembly tasks call for maximum feel. Here, 3–5 mil nitrile gloves make sense. They give almost bare‑handed touch, which helps when handling small terminals, pins, and clips, or when probing with meters in tight spaces.

We use these thinner gloves in areas where chemical exposure is low and the main risk is dirt or very light grime. The main compromise is shorter life. These gloves tear more easily under mechanical stress, so mechanics should plan to change them more often.

When we map out how to choose gloves for automotive work, we mark this thin range as a specialty option for high‑precision, low‑chemical tasks.

General Repairs and Maintenance

For the wide middle of shop work, we again land on 6–8 mil nitrile gloves. Suspension work, under‑hood repairs, cooling system service, basic drivetrain tasks, and body panel removal all fit well in this range. The gloves are tough enough to handle sharp brackets and tools, yet flexible enough to run ratchets and hand tools comfortably.

We often tell shops that these gloves should make up most of their stock, with thinner and thicker types used as needed. In the big picture of how to choose gloves for automotive work, this range becomes the backbone of a simple, effective glove program.

Proper Storage and Handling for Optimal Performance

Even the best nitrile glove can fail early if it is stored poorly. Heat, light, and ozone slowly break down rubber materials, making them brittle and weak. When we teach how to choose gloves for automotive work, we also explain how to keep those gloves in good shape until they are used.

Basic storage tips:

- Keep gloves in their original box or packaging.

- Store in a cool, dry place away from direct sunlight or heaters.

- Avoid placing boxes near welders, electric motors, or other ozone sources.

- Rotate older stock to the front so it gets used first.

Most disposable nitrile gloves last about three to five years when stored under these calmer conditions. Check the manufacturer’s shelf‑life guidance on the box if it is listed.

It is also important to remember that disposable gloves are made for one‑time use. Reusing them might look thrifty, but it brings real risk. Tiny holes from the first job may not be visible, yet they let chemicals or grime touch the skin on the next job, a contamination risk highlighted in studies on Preventing outbreaks in burn units that emphasize proper glove hygiene protocols. Reuse also spreads dirt and fluids between vehicles or systems, which hurts both safety and work quality.

Environmental Considerations: Sustainable Options for High-Volume Use

A busy shop can go through boxes of disposable gloves each week, which raises fair questions about waste. When we look at how to choose gloves for automotive work with the environment in mind, biodegradable nitrile is worth a close look. These gloves are made to break down faster in landfill settings compared with standard nitrile, often in years instead of many decades.

The key point is that quality biodegradable nitrile still matches regular nitrile in chemical resistance, strength, and dexterity while in use. They should feel and perform the same during a job. Prices often track near other premium nitrile lines, which keeps them realistic for many shops.

However:

- Used gloves soaked with hazardous chemicals still need proper disposal.

- Local regulations may treat some used gloves as hazardous waste.

- Shops should review their waste‑handling rules before switching products.

At Nitrile Gloves Info, we track new data on these greener options for readers who want to cut waste without giving up hand protection.

Conclusion

Choosing disposable nitrile gloves is not a small buying decision. For anyone focused on how to choose gloves for automotive work, it is a safety choice that shapes skin health, grip, and even the quality of finished repairs. Hands are the main tools in every shop, and they deserve the same careful planning that goes into lifts, torque wrenches, or diagnostic gear.

The core points are straightforward:

- Nitrile is the best all‑around material for automotive work because it resists oils, fuels, and many solvents better than latex or vinyl.

- Thickness sets the balance between feel and protection: 3–5 mil for precision, 6–8 mil for most day‑to‑day repairs, and 8+ mil for heavy chemical exposure and rough jobs.

- Powder-free designs protect paint and assemblies from stray dust, while texture supports a strong grip on oily parts and tools.

Fit and sizing matter just as much as any other spec when deciding how to choose gloves for automotive work. A well‑fitted glove lets the hand move freely and work longer without strain. Different tasks also call for different gloves, so a smart shop keeps a small range of thicknesses and styles ready instead of relying on a single box for everything.

At Nitrile Gloves Info, we focus on clear, technical guidance so mechanics, safety managers, and procurement staff can choose with confidence. With the details in this guide, anyone can set up a glove selection that protects hands, supports clean work, and matches the real demands of automotive service.

FAQs

What Makes Nitrile Gloves Better Than Latex or Vinyl for Automotive Work?

Nitrile stands out because it handles oils, fuels, and many solvents much better than latex or vinyl. It is three to five times more puncture resistant than latex at the same thickness, which matters around sharp metal and tools. Nitrile is also latex‑free, so it avoids allergy issues. Vinyl costs less but tears faster and offers weak chemical protection, so it does not meet most shop needs.

How Do I Know If a Glove Has Adequate Chemical Resistance for Brake Fluid?

For brake work, we always suggest checking the glove box and technical data, not just trusting the color or thickness. Look for markings such as EN ISO 374-1:2016, which show that the glove was tested against listed chemicals. Then read the maker’s chemical chart and confirm that common brake fluids, like DOT 3 and DOT 4, are covered. In most cases, we favor 8+ mil nitrile gloves that list strong resistance to these fluids.

Can I Reuse Disposable Nitrile Gloves to Save Money?

We strongly advise against reusing disposable nitrile gloves, even if they look fine at a glance. Small cuts or pinholes from the first use may not show, but they can still let oil, fuel, or cleaners reach the skin. Used gloves also carry grease and grime from one area or vehicle to another, which can damage paint or sensitive parts. The small cost saved does not outweigh the higher risk to health and work quality.

What Glove Thickness Should I Use for Oil Changes?

For oil changes, 6–8 mil nitrile gloves usually work best. They resist engine oil well and hold up against sharp threads and edges around the pan and filter. This thickness also gives enough feel to run tools comfortably and reach into tight spots. In our guides on how to choose gloves for automotive work, we list 6–8 mil nitrile as the standard choice for most fluid service.

Why Are Powder-Free Gloves Required for Automotive Work?

Powder‑free gloves protect both the vehicle and the repair. The cornstarch powder used in older styles can drift onto wet paint and leave small defects in the finish. It can also interfere with windshield sealants, body adhesives, and clean engine or transmission parts. Modern powder‑free nitrile uses smooth inner coatings so it still goes on easily. For anyone focused on how to choose gloves for automotive work, powder‑free is the only professional option.

How Do I Find My Correct Glove Size?

Start by measuring around the widest part of the hand, just below the knuckles and without the thumb. Compare that number to the size chart on the glove box, keeping in mind that Medium often covers about 20–22 cm and Large about 22–24 cm. A glove that slides around or bunches up is too big, while one that strains at the seams is too small. When testing a new brand for how to choose gloves for automotive work, we like to order two nearby sizes and see which feels snug but comfortable duri